Compressed Insulation

It’sec slowly to assume that the more insulation stuffed into your wall or ceiling cavities, the better the thermal resistance of this layer. However, because of the blueprint of sure insulation material as well as how they role, this compression actually compromises the ability of the cloth to finish rut.

Saying that compression is bad is an accurate blanket statement, simply it tin depend on the insulation fabric together with the degree of compression.

Insulation works by trapping air. Compressing air pockets means reducing R-value. Fiberglass, cellulose, together with mineral wool are virtually severely affected by compression. Natural fiber together with plastic fiber are slightly less affected. Compression is not a business organisation for foam.

What Compression Does to Insulation

Fiberglass

Fiberglass insulation plant past creating lots of tiny pockets of “dead” air infinite.

Trapping air is a 2-role function for fiberglass insulation.

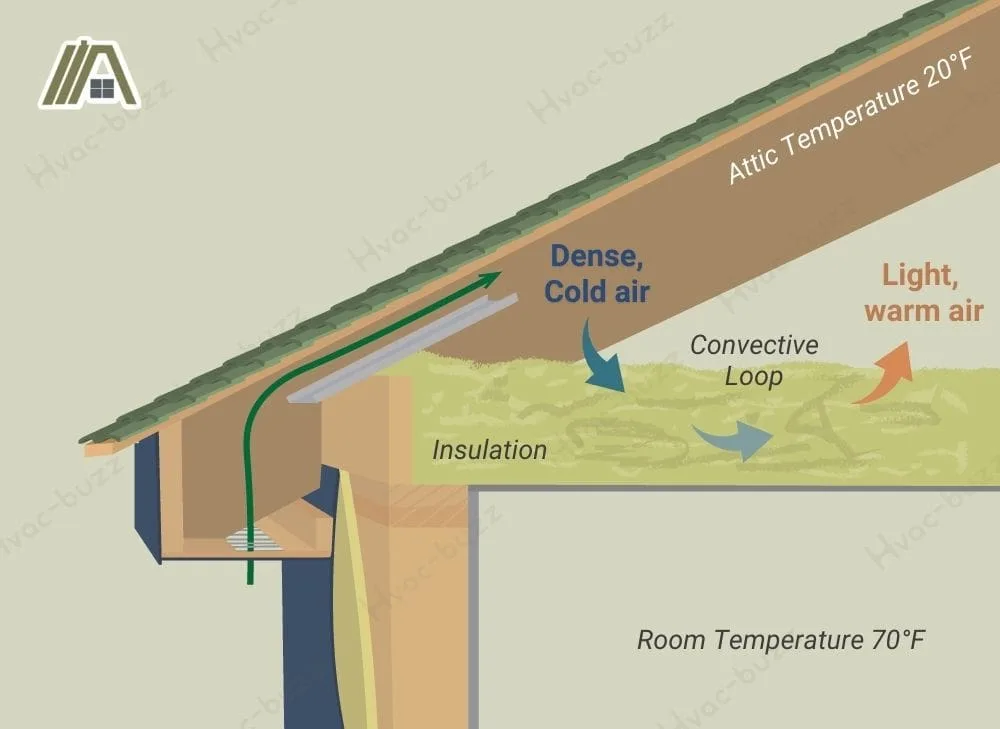

Firstly, trapping the air slows or stops convection, which is when air naturally moves from an surface area of higher temperature to an expanse of lower temperature.

Secondly, trapped air has limited drive, in addition to it becomes more than even so. Still, air is a pitiable conductor of oestrus energy via conduction.

Perfectly however, dry out air would theoretically take an R-value of three.vi per inch. In the early on as well as mid-twentieth century, architects too builders believed that 4 inches of dead air space too a vapor barrier could insulate walls. Now, nosotros know that air is never genuinely withal, and then nosotros function insulation to ho-hum downwardly air.

So, the spaces inwards betwixt fiberglass strands wearisome downward air, reducing how much heat it tin can transfer every bit it passes through the walls or attic.

When yous compress fiberglass, you lot cut back or destroy many of these dead air spaces.

In addition, compressed or settled fiberglass will likely non fill up the entire cavity, and then air will menstruation through the empty space.

In other words, compressed fiberglass leaves also many big air pockets (which allow air to flow) together with non enough tiny air pockets (which tiresome down air).

Completely filling the space with compressed fiberglass would prevent the issue of large gaps. Still, the compression itself would trim back the R-value.

At the end of the article, yous volition observe tables of R-value reduction for different levels of compression of the unlike insulation materials.

Cellulose

Cellulose works similarly to fiberglass inward that it prevents heat transfer because air moves really slow through it.

Packing it down runs the hazard of limiting the sum of dead air space inside the cellulose as well as creating larger gaps about the cellulose through which air tin can act.

Both cellulose too fiberglass come up in ii forms: blown-inwards loose fill up vs. batts. All blown-inwards insulation runs the adventure of settling nether the weight of gravity in addition to creating spaces for airflow. But cellulose settles more than any other type.

Standard levels of settling tin crusade cellulose to lose every bit much equally twenty% of its R-value over time. By contrast, fiberglass is alone expected to lose nearly ii-four% of its R-value due to natural settling.

To fighting settling, insulation contractors tend to install extra cellulose (aka “packing” cellulose) to eventually expand to fill up inward the gaps. Essentially, this type of “good” compression ultimately serves to fluff upwardly the cellulose over again.

This type of compression is done carefully in addition to intentionally. Contractors empathise how much extra is needed based on the type of cellulose.

Mineral Wool

Mineral wool (likewise called Rockwool as well as stone wool) plant much like fiberglass. Its open up-cell matrix traps air as well as prevents it from moving.

Yet mineral wool is much firmer as well as denser than fiberglass. Because of this, it has a higher R-value and is more than expensive than fiberglass.

Mineral wool’s high density too way that it is more than physically hard to compress than fiberglass, which is more than flexible together with, inward a manner, delicate. In fact, mineral wool is basically already compressed in the manufacturing procedure.

You may have read elsewhere that because it is already then dense, mineral wool either won’t be harmed past compression or cannot live compressed inwards the kickoff place.

However, testing shows that the R-value of mineral wool is reduced—though non equally much as fiberglass or cellulose—specially at high levels of compression (more than xx%).

If you lot take to tally mineral wool into a shallower infinite than it is designed for, you lot tin can shave off a layer past slicing the batt amongst a knife.

Whenever possible, purchase insulation inward the right dimensions in addition to function it as directed.

Natural Fiber

Natural fiber insulation includes many types of insulation made from things like sheep’second wool, cotton fiber, in addition to hemp.

Sheep’s wool insulation loses R-value when compressed, merely it’s more than resilient than fiberglass, cellulose, or mineral wool. Still, compressing sheep’s wool or cotton insulation will squish the natural air pockets created past the crimped construction of the fibers.

In just about cases, the manufacturing procedure involves rolling the fibers into “air-capturing balls” that you lot should try not to squish likewise much. Every air-capturing bag is a chance to forestall rut transfer.

Unlike mineral wool, which volition return to its master thickness fifty-fifty later being significantly compressed inwards packaging, cotton batts sometimes make not spring dorsum into shape.

There have been reports of certain cotton insulation failing to “fluff up” to total size when opened. In those unfortunate cases, the buyer cannot attain the advertised R-value.

Hemp insulation is much stiffer together with denser than sheep’second wool or fiberglass. It’s fairly difficult to compress alongside your hands and volition bounce back afterward existence compressed. Still, it traps rut inwards air pockets, and then y'all should avoid permanently compressing it.

Plastic Fiber

Plastic fiber insulation is made from recycled milk bottles (polyethylene terephthalate or PET). The fibers from this type of plastic are formed into batts that somewhat resemble fiberglass just are denser.

Plastic fiber insulation behaves similarly to fiberglass batts inward that it operates by trapping air inside small-scale gaps betwixt fibers. Again, this means that compression will trim back gaps in addition to trim back opportunities for trapping air, ultimately reducing the R-value.

Because it’s already denser than fiberglass or cellulose, plastic fiber insulation volition non decrease inward R-value equally dramatically as other types of insulation.

Plastic fiber as well as sheep’sec wool decrease inward R-value when compressed, simply less than fiberglass together with cellulose. Still, after fifty% compression, you’re looking at a huge loss in R-value.

Spray Foam

Foam holds tiny air pockets, then you lot would think that compression could be an result. However, at that place is non much discussion or concern amongst contractors near compressing spray foam insulation. There are several reasons for this.

Firstly, foam does non settle. This means that in that location are no issues amongst natural compression due to settling or with DIYers overfilling to counteract settling.

Secondly, you lot generally would non take a reason to compress spray foam. When fiberglass batts go compressed, it is sometimes because individual bought also thick of a batt for their wall cavity. By contrast, spray foam tin fill up whatsoever sized cavity, large or pocket-sized.

In fact, spray foam is oft suggested every bit a mode to avoid compressing fiberglass batts around windows or inwards awkward spaces.

Typically, the foam is sprayed inward 2-inch “lifts,” which are allowed to cure earlier the next lift, ensuring that y'all know how thick the cured layer ends upwardly existence.

At the finish, you lot scrape off extra foam (“overspray”) earlier finishing the wall rather than compressing the overspray.

Low-density open up-cell spray foam stays somewhat flexible after it cures, so I suppose that some degree of compression could pass off if you lot tried. However, in almost cases, compression is non a common business surrounding spray foam.

Rigid Foam Boards

Rigid foam boards are an ideal pick for those worried well-nigh the effects of compression. Rigid foam is real durable together with does not settle. In fact, stiff foam boards make not fifty-fifty compress!

The master deviation betwixt foam board in addition to other types of sail or blanket insulation is that foam board is extremely strong. It tin live cut with a knife only it volition non go accidentally torn.

You besides do not take to worry near compressing it during installation, whereas virtually insulation batts get partly compressed when stapled to the wall.

Basically, rigid foam board is dense and already compressed. It comes in unlike thicknesses (virtually frequently 2 inches thick) and tin live easily layered without worrying most compressing the board underneath.

The one thing to note near foam board is that you lot cannot leave it exposed. Building code requires y'all to have a thermal barrier for burn rubber.

Compression Reduces R-Value

Because compression affects the manner that the materials human action equally insulators, it reduces the R-value of the fabric.

The following tables calculate how much the R-value decreases when dissimilar types of insulation are compressed by a sure percent.

Calculations are based on charts provided past manufacturers in addition to contractors. Numbers volition vary past product in addition to state of affairs.

Spray foam as well as stiff foam boards make not take tables because compression is not a serious enough job for the manufacturers of those materials to provide information about it.

Fiberglass

| Compression Percentage | R-Value Reduction |

| 2 | two.vii% |

| 5 | 4% |

| ten | 6% |

| 20 | 17% |

| l | 44% |

| lx | l% |

| fourscore | Data is insufficient to decide this per centum; suggests really few people endeavor to compress fiberglass more than than lx%. |

Cellulose

| Compression Percentage | R-Value Reduction |

| 2 | 6% |

| five | 14% |

| x | 20% |

| fifteen | 25% |

| twenty | 31% |

| 50 | lx% |

| 80 | 85% |

Mineral Wool

| Compression Percentage | R-Value Reduction |

| two | two% |

| v | v% |

| ten | 9% |

| twenty | xvi% |

| l | 38% |

| lxxx | 70% |

Natural Fiber

The next tabular array is specifically for sheep wool insulation, i type of natural fiber insulation. Other material similar cotton, hemp, or straw may yield unlike results.

| Compression Percentage | R-Value Reduction |

| ii | 0.v% |

| v | ane% |

| ten | ii% |

| twenty | iv% |

| fifty | 19% |

| 80 | lx% |

Plastic Fiber

| Compression Percentage | R-Value Reduction |

| two | 0.5% |

| 5 | one.5% |

| 10 | iv.v% |

| twenty | seven.5% |

| 50 | 24% |

| eighty | 57% |

Comments

Post a Comment